Mil-spec webbing is designed and manufactured following U.S. military standards (MIL-SPEC) to ensure strength, durability, and consistency in demanding environments. These standards regulate material quality, weaving precision, and performance characteristics to meet the needs of tactical gear, load-bearing equipment, and military accessories.

The production process of mil-spec involves careful material selection, precise weaving, dyeing, and finishing techniques, all of which adhere to strict military specifications. To guarantee reliability, the webbing undergoes tensile strength, abrasion resistance, and durability testing, ensuring it meets operational requirements. Mil-Spec webbing is widely used in tactical vests, harnesses, belts, and modular attachment systems, where consistent performance is essential for safety and functionality.

Our mil-spec webbing is made from high-strength nylon and polyester, ensuring durability and resistance to wear. Nylon provides excellent tensile strength and flexibility, while polyester offers better resistance to moisture and UV exposure. Designed for military use, our webbing performs reliably in extreme conditions.

A-A-55301 is a recognized U.S. military standard nylon webbing, known for its durability, flexibility, and resistance to wear. This specification ensures that the webbing meets strict performance criteria, making it widely used in tactical vests, military gear, and load-bearing equipment. While strong and abrasion-resistant, it remains lightweight and flexible, allowing for ease of handling in various applications.

Note: Webbing test reports available. Printed camouflage A-A-55301 webbing is also available upon request.

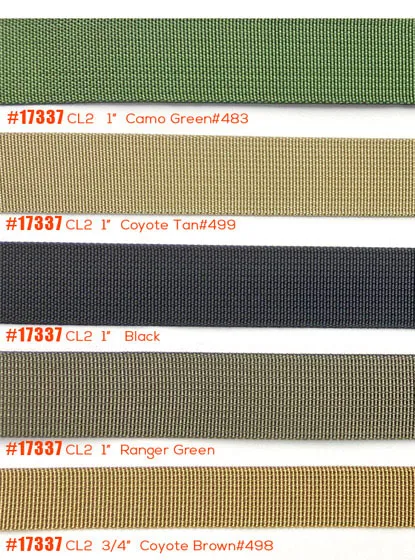

This type of military-grade nylon webbing is commonly known as MOLLE webbing or PALS webbing and is designed to meet U.S. military specifications. It provides high durability, strength, and resistance to wear, making it ideal for soldier systems, tactical vests, modular attachment setups, and load-bearing equipment. Its structured design allows for secure gear attachment, ensuring stability and reliability in military, tactical, and outdoor applications. Additionally, it is widely used in rucksacks, military luggage, and other field equipment requiring strong and flexible webbing.

Note: Webbing test reports available. Printed camouflage MIL-W-17337 webbing is also available upon request.

Designed for military and aerospace applications, this heavy-duty structural webbing offers exceptional strength and durability. It is commonly used in parachutes, harnesses, tie-down systems, COBRA® belts, cargo nets, and other aeronautical safety equipment. The PIA-T-27265 variant features a resin treatment, enhancing resistance to wear, moisture, and environmental stress, making it ideal for high-performance load-bearing applications.

Lightweight and durable, these plain-weave binding tapes meet MIL-T-5038 military specifications, making it suitable for apparel, rucksack binding, and reinforcement applications. Its flexibility and strength provide secure edging and structural support, ensuring long-term durability in both tactical and everyday use.

Note: Other variations, including camouflage versions of MIL-T-5038, are also available upon request.

Designed for high-strength applications, this tubular webbing meets MIL-W-5625 military specifications and is widely used in parachute construction, climbing straps, and load-bearing systems. Its tubular design provides increased flexibility and shock absorption, making it ideal for applications requiring durability and controlled stretch.

At Jude, we focus on delivering high-performance webbing solutions designed to meet a wide range of functional needs. Whether you require webbing for military, outdoor, safety, or specialized applications, our products are engineered to deliver reliability and durability.

As a specialized webbing manufacturer, we operate a 25,800m² production facility with full in-house capabilities, including weaving, printing, dyeing, and assembly. With over 30 years of industry experience, we understand that material selection plays a key role in webbing performance.

Polypropylene webbing, also known as PP webbing, is a lightweight and durable solution made from polypropylene fibers. Commonly used in bags, apparel, home textiles, and industrial applications, it offers a balance between strength, functionality, and cost-effectiveness.

Our expert team is ready to help you choose the best webbing solution.

Nearly 20 years of experience in the webbing industry

25,800m² production facility with integrated weaving, dyeing, printing, and finishing operations

Daily output exceeding 300,000 meters